Heavy fabrication is a specialized sector within the manufacturing industry that involves creating large and complex structures, primarily using metal materials. This process encompasses various activities, including cutting, welding, machining, and assembling metal components to form finished products. Heavy fabrication is crucial for several industries, including construction, energy, transport, and manufacturing, as it contributes to infrastructure development and the production of essential machinery and equipment.

Understanding Heavy Fabrication

At its core, heavy fabrication is about transforming raw materials into valuable products that meet specific functional requirements. The materials commonly used in heavy fabrication include steel, aluminum, and other alloys, which are selected for their strength, durability, and resistance to environmental conditions. The processes involved in heavy fabrication are often carried out in large manufacturing facilities equipped with specialized tools and machinery designed to handle heavy loads.

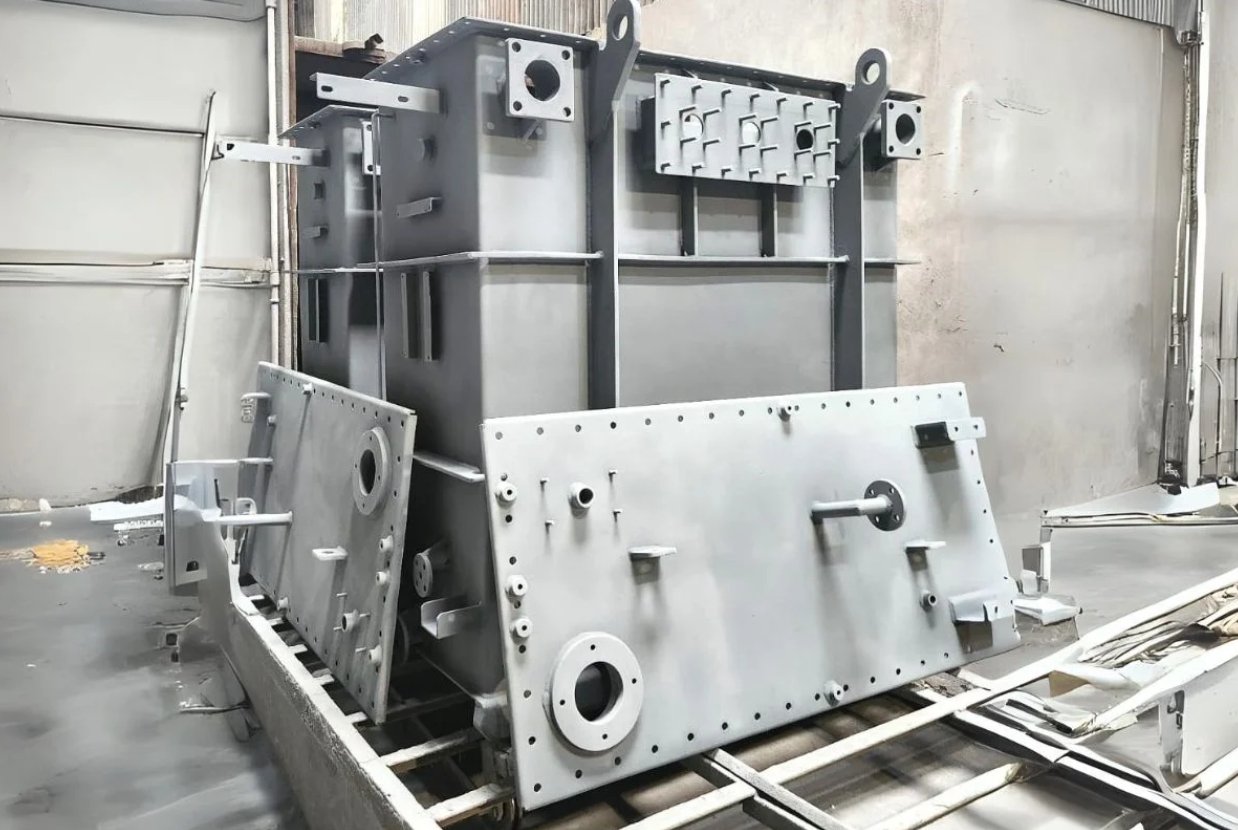

Heavy fabrication is characterized by the scale and complexity of the projects undertaken. Unlike light fabrication, which may focus on smaller components, heavy fabrication deals with significant structures, such as bridges, large tanks, and industrial machinery. This necessitates a high level of expertise and precision, as the components produced must meet stringent quality and safety standards.

Key Uses of Heavy Fabrication

- Infrastructure Development: One of the most visible applications of heavy fabrication is in infrastructure development. This includes constructing bridges, tunnels, and high-rise buildings. Heavy fabricated components provide the necessary strength and stability to support these structures, ensuring they can withstand heavy loads and adverse weather conditions.

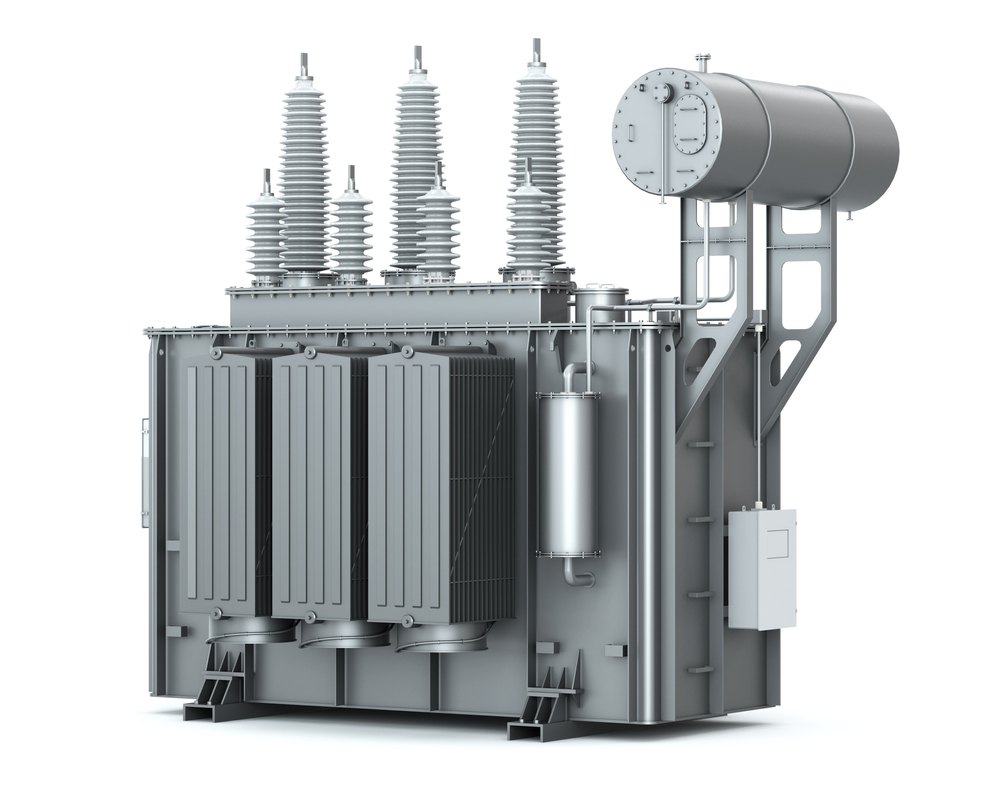

- Energy Sector: The energy industry heavily relies on heavy fabrication for the production of components used in power generation. This includes heat exchangers, pressure vessels, and piping systems, which are essential for power plants and oil refineries. The fabrication of these components requires specialized techniques to ensure they can handle high pressures and temperatures safely.

- Transport Industry: Heavy fabrication plays a critical role in the transport sector, particularly in the production of railway components, locomotive parts, and heavy machinery. These fabricated products are essential for ensuring the safe and efficient operation of transport systems, from trains to construction equipment.

- Manufacturing: In the manufacturing sector, heavy fabrication is vital for producing customized machine parts that enhance operational efficiency. Businesses often require specific components tailored to their processes, and heavy fabrication allows for the creation of these specialized parts, ensuring optimal performance and productivity.

Shrao Engineering: A Leader in Heavy Fabrication

At Shrao Engineering, we pride ourselves on being a leading heavy fabrication company in India. With over 40 years of experience, our ISO-certified facility in Bhopal is equipped to handle a wide range of fabrication projects. We specialize in manufacturing high-quality products, including transformer tanks, industrial components, and customized solutions for various industries.

Our commitment to innovation, quality, and customer satisfaction sets us apart in the heavy fabrication industry. We understand the unique requirements of our clients and work closely with them to deliver tailored solutions that meet their specific needs.

If you’re seeking a dependable partner for your heavy fabrication needs, look no further than Shrao Engineering. With our extensive expertise and unwavering commitment to quality, we are well-equipped to support your projects. Visit our website to discover how our comprehensive heavy fabrication services can help turn your vision into reality. Let us collaborate with you to achieve your goals efficiently and effectively.