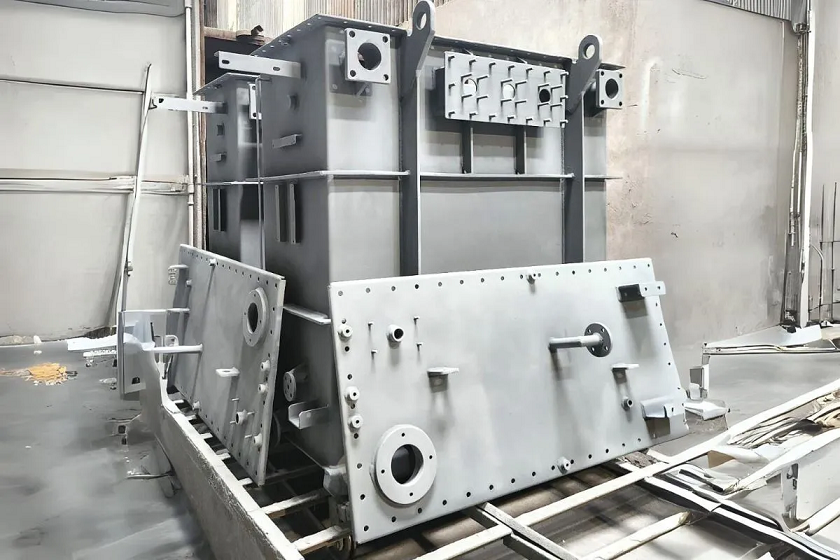

Transformers are vital components in power transmission and distribution systems, ensuring the efficient transfer of electrical energy. However, the role of transformer tanks in safeguarding these crucial devices is often overlooked. The size and shape of a transformer tank significantly influence its performance, durability, and suitability for various applications. Choosing the right transformer tank design is essential for optimizing efficiency, reducing maintenance costs, and ensuring long-term reliability.

The Importance of Transformer Tank Size

The size of a transformer tank directly impacts the transformer’s cooling efficiency, oil capacity, and overall operational performance. A transformer generates heat during operation, and the tank holds insulating oil that helps dissipate this heat. If the tank is too small, it may not hold enough oil for effective cooling, leading to overheating and potential failure. Conversely, an oversized tank can lead to unnecessary material costs and space constraints without providing proportional benefits.

Transformer tanks are designed to accommodate specific voltage ratings, load capacities, and environmental conditions. A well-proportioned tank ensures that the transformer operates within safe temperature limits, extending its lifespan and minimizing the risk of faults. Engineers consider factors such as oil expansion, pressure control, and heat dissipation while determining the ideal tank size for a given transformer.

How Shape Affects Performance

The shape of a transformer tank is another crucial factor influencing its efficiency and durability. Common tank shapes include rectangular, cylindrical, and finned designs, each offering distinct advantages based on the application.

- Rectangular Tanks: Widely used in power transformers, these tanks provide structural stability and accommodate cooling fins to enhance heat dissipation. They are easier to manufacture and install in various settings.

- Cylindrical Tanks: These are often preferred for smaller distribution transformers due to their compact design and ability to withstand internal pressure variations effectively.

- Finned Tanks: Designed with additional surface area to improve heat dissipation, finned tanks are ideal for high-power applications where efficient cooling is essential.

The shape also influences the tank’s ability to withstand mechanical stress, pressure fluctuations, and environmental factors. A well-engineered tank shape ensures optimal performance and prevents leaks or deformations under extreme conditions.

Choosing the Right Transformer Tank for Your Needs

Selecting the appropriate transformer tank size and shape requires careful consideration of various factors, including load capacity, cooling requirements, environmental conditions, and space availability. Consulting experienced engineers and reliable manufacturers can help determine the best design for your specific needs.

At Shrao Engineering, we specialize in precision-engineered transformer tanks tailored to diverse industrial applications. As a trusted transformer tank manufacturer and transformer tank supplier, we ensure high-quality fabrication, durability, and compliance with international standards. Our expertise in designing and manufacturing transformer tanks enables us to provide efficient, long-lasting solutions for power distribution and industrial applications. Contact us today to explore our range of transformer tanks and find the perfect fit for your requirements. Contact us today to find the perfect transformer tank for your application.